Expansion Joint Cover

Expansion Joint Cover is a cover or a covering system that protects the structural gap designed to accommodate the movement of the building in a controlled to prevent damages to the building finishes. It remains unaffected by the relative movement of the two surfaces on either side of the joint and provides a smooth transition across an expansion joint opening.

Expansion Joints is essential to the building because it gives some flexibility when movement occurs due to thermal, settlement, wind-sway, or seismic activity. The gap or the joint width varies depending on the geographical location of the building and the height of the building. Usually, as the building goes higher, the gap will become bigger.

There are a wide variety of Expansion Joint Covers available now in the market. You can choose what type of expansion joint covers that will suit your requirements and best fit as per your site condition.

Expansion Joint runs throughout the building floors, walls, and ceilings, so wall and ceiling gap also needs a cover. Most of the expansion joint covers for the walls can be applied also in the ceiling but some ceilings require special covers, like for the suspended ceiling, etc.

The expansion joint cover is a key component in concrete structures that allows for the movement of thermal and seismic activity. Understanding these two factors is critical to understanding why it’s important to use the right type of expansion joint cover when building your structure. The wrong type can lead to damage over time, which will need costly repairs or replacement.

The expansion joint cover has different terms, depending on the material it is made from. The type of expansion joint cover needed for your structure depends on a number of factors including the size and width of expansion joints in need; directionality (if movement occurs horizontally or vertically); level to which it will be exposed to environmental elements such as water and air; and the structure itself (for example, if it is a large-span building).

The expansion joint cover can be made from many different types of materials including elastomeric rubber for flexible expansion joints; aluminum expansion joints which are used in high traffic areas and offer insulation properties; steel or thick aluminum expansion joints which are used for heavy traffic areas and offer high load-bearing and abrasion resistance.

The expansion joint cover has to be the right width in order for it to fit properly into expansion joints that have been built into concrete structures. The wrong type of expansion joint cover can cause structural damage and lead to expensive repairs.

The expansion joint cover in concrete is an accessory that is designed to allow the material to expand and contract with the thermal movement. The expansion joints are also opened or closed depending on the seismic activity. The expansion of these joints allows for less stress on the concrete structure, which will help it last longer.

Thermal Movement in Concrete Structures

The expansion joint covers are used in concrete to allow structures to accommodate the thermal and seismic activity. This blog post is for Architects and Contractors to educate them on thermal and seismic movement and the damage that it can cause structures over time.

In order for a building or other structure made of concrete not only to endure but also to maintain its integrity, expansion joints must be incorporated into the design from the beginning.

These expansion joints are small gaps between adjacent slabs of concrete that allow room for expansion as well as contraction due to temperature changes. They should never be placed less than 5 feet apart vertically or horizontally, otherwise, they will experience excessive pressure from one another during expansion and contraction cycles, causing cracks and other structural defects known as spalling. Thermal movement refers to expansion and contraction in concrete structures which happens due to expansion and contraction of the concrete.

Thermal movement can also cause other problems such as corrosion, cracking, staining or scaling (i.e., flaking). This is why it’s extremely important for Architects and Contractors to understand thermal expansion joint covers because if they don’t this could lead to major structural damage over time.

- expansion joints should never be placed less than five feet apart vertically or horizontally

- Thermal Movement: expansion/contraction cycles in a concrete structure caused by temperature changes

- spalling: cracks that develop due to pressure from one another during expansion and contraction cycles

Seismic Movement in Concrete Structures

Seismic movement is the expansion and contraction of a structure due to natural forces. In concrete structures, expansion joints are used as a way for this expansion and contraction to occur without damage. Expansion joint covers typically have an air space between them that will allow expansion, but not compression. This blog post is intended for architects and contractors who need more information on how expansion joint covers work in order to educate their clients about seismic movement in concrete structures.

Seismic expansion joints are a common feature in concrete structures. They allow expansion of the structure due to natural forces, but not compression.

This is important because if there were no expansion joints, the building would be subject to damage from the expansion and contraction of the structure. Seismic movement can also cause cracks in concrete structures that have been poorly designed or constructed. As such, it’s important for architects and contractors to understand how expansion joint covers work so they can educate their clients on this topic.

Risks of not using Expansion Joint Covers

Expansion joint covers work to protect your structures from expansion and contraction due to various factors such as temperature changes, seismic activity, etc. These expansion joints allow the concrete structure to move without any damage occurring.

If you are an architect or contractor who is designing a new building or repairing an old one it’s important that you understand expansion joints for concrete structures because they can save your project from serious structural damages over time. If you don’t install expansion joint covers in your building, these movements will cause cracks that are not only unsightly but also destructive. Cracks lead to more problems like water infiltration which can result in mold growth and lead to deterioration of the building materials themselves! That’s why expansion joint covers are very important.

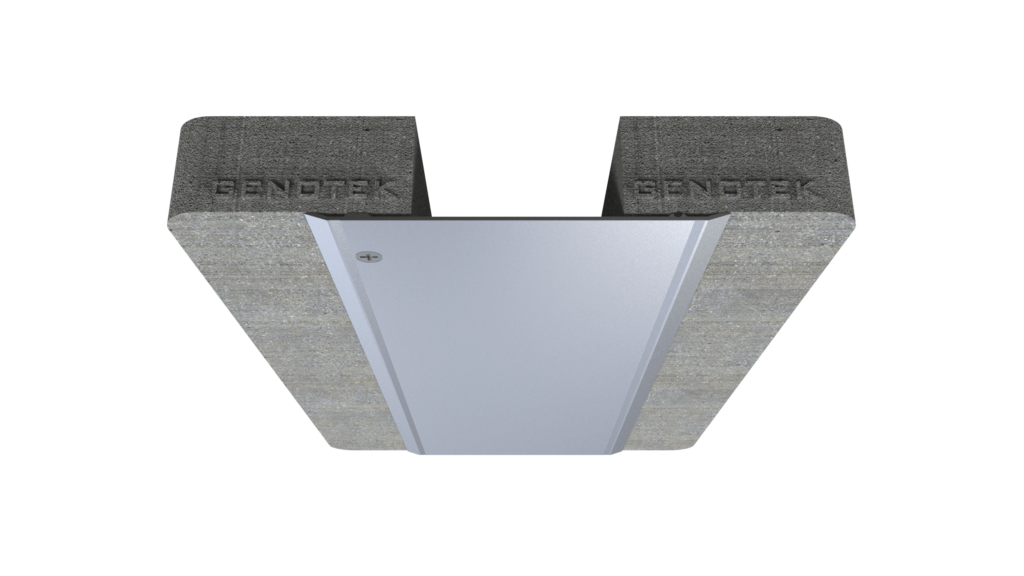

Rise and Shine Technical Services OMAN is proud to announce that we have been approved as an authorized applicator of Genoteck expansion joints. This recognition is a testament to our expertise and commitment to providing high-quality services to our clients.

Genoteck is a trusted name in the construction industry and their expansion joints are known for their durability and long-lasting performance. As an approved applicator, we have undergone rigorous training and testing to ensure that we meet the highest standards of quality and workmanship.

We are excited to offer our clients the benefits of Genoteck expansion joints, including improved structural integrity, reduced maintenance costs, and increased lifespan of their buildings. With our expertise and the superior quality of Genoteck products, we are confident in our ability to provide outstanding service and results for all our clients’ expansion joint needs.

Contact Us

Venkadesh Nammalvar

Project Sales Engineer

- +968 9147 1807

- omansales1@rnsmail.net

Approved Applicator Certificate

Rest of the World

South Africa

THE GAUTRAIN

Batam

CIBA VISION

Malaysia

MID-VALLEY SHOPPING CENTRE

Belfast, Northern Ireland

TITANIC SIGNATURE BUILDING

Hanoi

INTERCONTINENTAL HOTEL

Australia

ADELAIDE TERRACE – Perth

Hong Kong

HONG KONG CX CARGO HUB

London

THE PALACE OF WESTMINSTER

England

HEATHROW TERMINAL 5

Singapore

IKEA TAMPINES MALL

Macau

WYNN RESORT

Bangkok, Thailand

IMPACT ARENA

Useful Links

Contact Us

Share with Us

Copyright @ 2022 Rise & Shine Group. All Rights Reserved.